Gravity Conveyors

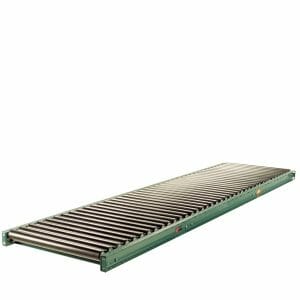

Gravity conveyors are a fundamental component in the material handling industry, serving as an economical and efficient means of moving goods. Utilizing the natural force of gravity, these conveyors provide a simple yet effective solution for transporting items across a decline or along a level surface when manual assistance is employed.

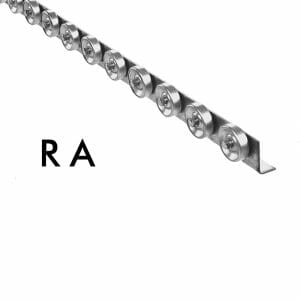

Constructed with durable materials such as galvanized steel or aluminum, gravity conveyors are built to support a wide range of weights and sizes of products. Their design typically features rollers or skate wheels, which create a smooth and effortless flow of materials, minimizing the need for power sources or complex machinery.

These conveyor systems are highly versatile, offering flexibility in configuration to fit various spaces and applications. They can be straight, or curved, or come with adjustable heights and lengths, catering to specific operational needs. This adaptability makes them suitable for industries ranging from warehousing and distribution to manufacturing and retail.

Gravity conveyors are favored for their ease of installation, low maintenance requirements, and the ability to increase the speed of production processes. They are particularly beneficial in areas such as shipping and receiving, assembly lines, and packaging stations, where they contribute to a seamless transition between different stages of production and distribution.

Safety is also a key feature of gravity conveyors. With minimal moving parts, they present fewer risks than motorized systems and often include safety guards and stops to protect workers.