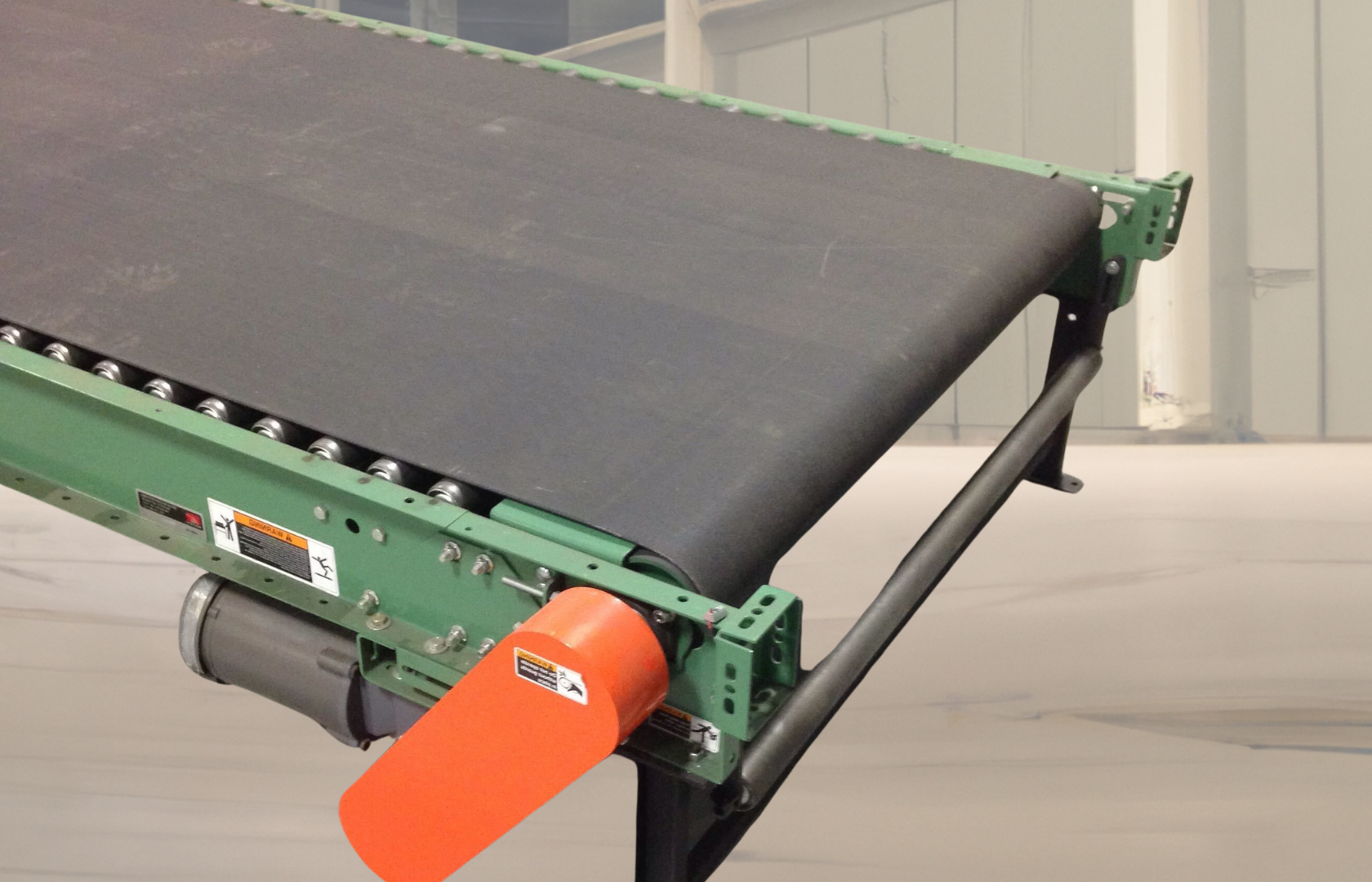

Belt Conveyors

The industry's most straightforward and adaptable material handling system is the belt conveyor. By means of an unending loop belt driven by two or more pulleys, they effectively transport goods from one location to another. The ease of installation and their straightforward design and construction make these systems popular in industrial and distribution centers.

For many warehouse and industrial applications, belt conveyors provide an affordable solution. Totes, packaged goods, bulk cartons, and other items with both regular and irregular shapes are ideal choices for easy conveyance. Although its primary function is transportation, belt conveyors are not usually employed for part accumulation or buffering, nor are they utilized as a work surface for members of the production team.

These systems have the ability to transport goods in continuous or indexing modes, change speeds using a variable frequency motor, and move products up or down inclines (up to a maximum of 25 degrees). They can also be used to move goods around curves while preserving the correct alignment of the product.

There are a variety of belt material options available, such as chemically resistant belts, high-temperature resistant belts, rough top belts for added grip, and general-purpose belts. There are many different kinds of belt conveyors, including incline style, heavy-duty models, troughed belts with side rails, and belt curves. Belt conveyors come with various drive packages, mounting options, and belt widths up to 72 inches for heavy-duty applications. They can handle loads ranging from light to heavy. There are several customization choices and a range of lengths to accommodate various industrial applications.